Learninsta presents the core concepts of Microbiology with high-quality research papers and topical review articles.

Industrial Production of Single Cell Protein

Single cell protein refers to the microbial cells or total protein extracted from pure microbial cell culture (monoculture) which can be used as protein supplement for humans or animals. During ancient times, the tribes in the Central African Republic used a spiral shaped Cyanobacterium named Spirulina platensis as food.

They collected it as mats from the bottom of seasonally dried up ponds and shallow waters around Lake Chad and dried them in the sun and made small cakes called “Dihe”.

During the World war II, when there were shortage in proteins and vitamins in the diet, the Germans produced yeasts and a mould named Geotrichum candidum was used as food.

The term Single Cell Protein was coined by C.L Wilson (1966) at Massachusetts Institute of Technology (MIT), to represent the cells of algae, bacteria, yeasts and fungi, grown for their protein contents. The name was introduced by Prof. Scrimshow of MIT in 1967.

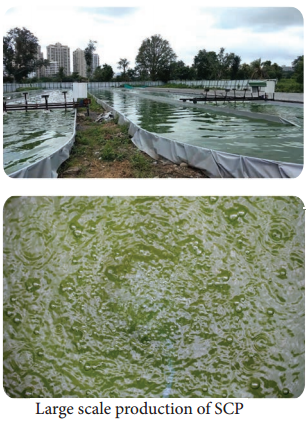

The organisms like Pseudomonas facilis, P. flava, Chlorella, Anabaena, Spirulina, Chlamydomonas, and Agaricus are commonly used for SCP production. Large scale production of SCP is shown in the Figure 6.11

There are several methods available for SCP production. In the Japanese method, flat tray is used with artificial sunlight algae are cultivated in shallow ponds with mechanical stirrers or in deeper ponds (not more than 20-30 cm deep) with circulation pumps. Optimum, light is an important parameter for maximum

growth of SCP. Scenedesmus sp. grows 20 times faster in optimum light than in natural conditions.

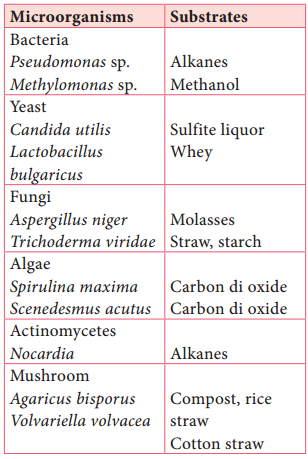

Optimum temperature and optimum pH is varied according to the strain and intensity of light. Example: Spirulina is cultivated at 25-35ºC with pH 9.5. Table 6.6 shows different types of microorganisms and substrates used for SCP production.

List of microorganisms and substrates used for SCP production

Steps involved in SCP production

Provision of carbon source with added nitrogen, CO2, ammonia, trace minerals for growth

↓

Prevention of contamination by using sterilized medium and fermentation equipments

↓

Selected microorganism is inoculated in a pure form

↓

Adequate aeration and cooling is provided

↓

Microbial biomass is harvested and recovered by flocculation or centrifugation flocculants

↓

Harvested algae are dewatered and dried on open sand beds

↓

Processing biomass and enhancing it for use and storage

Advantages of using microorganisms for SCP production:

- Microorganisms grow at a very rapid rate under optimal culture conditions.

- The quality and quantity of protein content in microorganisms is better compared to higher plants and animals.

- A wide range of raw materials which are otherwise wasted, can be fruitfully used for SCP production

- The culture conditions and the fermentation processes are very simple.

- Microorganisms can be easily handled and subjected to genetic manipulations.

During the cultivation of SCP, care must be taken to prevent and control the contamination by other micro organisms, which produce mycoxins or cyanotoxins. This is controlled by using the fungus Scytaliclium acidophilum which grows at a low PH. It allows the hydrolysation of paper wastes to a sugar medium and also creates aseptic condition at low cost.