Learninsta presents the core concepts of Microbiology with high-quality research papers and topical review articles.

Industrial Production of Wine

An alcoholic distilled beverage is produced by concentrating alcohol from fermentation by distillation. Beer or ale is produced by the fermentation of malted grains. Wine is prepared from grapes belonging to species Vitis vinefera. It is also produced from other fruits like peach, pear, dandelion and honey.

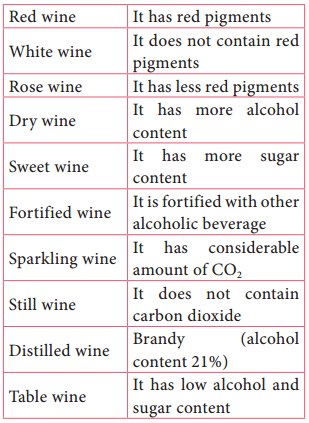

Generally wine contains 16% of alcohol. Wine production from crushed grapes is called enology. The various forms of wine are listed below in the table 6.5.

Shows diffrent varieties of wine

Red wine is extracted from the skin of red grapes containing red pigment (anthocyanin). During the preparation of red wine, all the anthocyanin pigments are solubilized by the extract. Pink wine is obtained from either pink grapes or red grapes in which fermentation last for only 12 to 36 hour and only less amount of anthocyanin pigments are solubilized. White wine is prepared from the white grapes or from the red grapes in which pigment involved in colouring is removed.

Generally yeasts are the natural microbiota of grapes

Both wild yeast and cultivated yeast are involved in the wine fermentation. Natural yeast is not potable because they do not produce much wine and are less alcohol tolerant and produce undesirable compounds, affecting the quality of the wine.

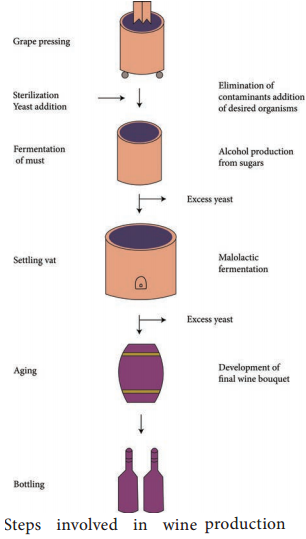

The cultivated wine yeast, Saccharomyces ellipsoideus, is used for commercial production. Figure 6.10 shows steps involved in wine production.

Steps involved in Wine production Grapes are stemmed, cleaned and crushed

↓

Sodium or Potassium Meta – bisulphate is added to check the undesirable microorganism

↓

Must (crushed grapes) is treated with Sulfur dioxide to kill the wild yeasts and bacteria or sometimes pasteurized to destroy the natural microbiota

↓

Must is inoculated with Saccharomyces ellipsoideus (2.5%) and selected fermentation is carried from 50 to 50000 gallons at 20 to 24°C

↓

Oak, cement, stone glass lined metal are used as fermentor

↓

Temperature and time required for fermentation White wine: 10 – 21°C, 7 – 12 days; Red wine: 24 – 27°C, 3 – 5 days

↓

In red wine production, after three to five days of fermentation, sufficient tanin and colour is extracted from the pomace and the wine is drawn off for further fermentation

↓

Racking improves flavour and aroma, where wine is separated from the sediment containing yeast cells as precipitate form

↓

The wine is subjected to aging at lower temperature. Ageing process is typically much longer for red wine than white wine

↓

Wines are clarified in a process called fining. Fining is done by filtration through casein, tannin, diatomaceous earth or bentonite clay, asbestos, membrane filters or centrifugation

↓

The wine produced is placed in casks, tank and bottles

After wine production, cork should be used for preventing the entry of air into the bottles. The presence of air allows the growth of vinegar bacteria that convert the ethanol to acetic acid. The final alcohol content of wine varies depending upon the sugar content of the grapes, length of the fermentation and type of strain used.