Learninsta presents the core concepts of Microbiology with high-quality research papers and topical review articles.

Industrial Production of Citric Acid

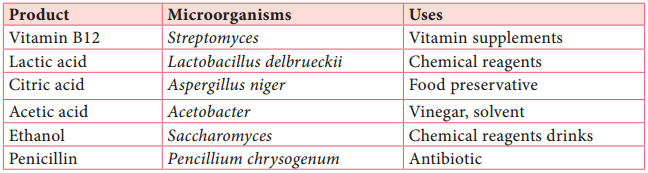

Citric acid is obtained from citrus fruits; pineapple etc., and after the development of microbial fermentation, citric acid production becomes very cheap, easy and cost effective. 70% of citric acid produced is used in food and beverage industry. Many microbial strains such as fungi Aspergillus flavus, Aspergillus niger and Trichoderma viridae, yeast Hansenulla polymorpha and Candida lipolytica are generally are involved in the production of citric acid.

Citric acid production can be carried out in the following three methods.

- Koji process or solid state fermentation

- Liquid surface culture

- Submerged fermentation

Media used in citric acid production

Citric acid production is carried out by using carbohydrates and n-alkenes. Generally beet molasses, cane molasses, sucrose, commercial glucose and starch hydrolysate are used as carbohydrate sources. The carbohydrate material is diluted and mixed with a nitrogen source (ammonium salts or urea) and the pH and temperature are adjusted according to the process.

Inoculum development

Fungal strains that are used for production are stored in soil or silica gel in the form of spores. Spores are suspended in a freshly prepared sterile water containing Tween 80 and after a period of growth, it can be used as inoculum for large scale production.

Steps involved in citric acid production

Production Medium

Sucrose, beet molasses, used as carbon source need pretreatment, as it contains excessive amount of trace metals. So ferrocyanide or ferricyanide is added to the production medium before sterilization. Inorganic salts, carbon, hydrogen, oxygen trace metals. Nitrogen, potassium, phosphorus,sulphur and magnesium

are taken in Aluminum or stainless steel shallow pans or tray (5-20 cm deep).

↓

Inoculated with spores of A. niger by blowing over the strains of Aspergillus niger for fermentation

↓

The medium is kept at 28-30ºC with relative humidity 40-60% and aerated with purified air for 8-12 days

↓

Citric acid produced is determined by checking the pH or the total acid content of the broth.

↓

Fermented liquid is drained off and processed further for the recovery of citric acid

Recovery

The mycelial mat is pressed.

↓

Milk of lime (calcium carbonate) is added so calcium citrate is formed.

↓

Again sulphuric acid is added, so calcium sulphate is formed.

↓

The remaining citric acid solution is filtered and washed. Finally the impure solution of citric acid subjected to treatment with activated carbon and finally pure form of citric acid is collected.

Uses

It is used as a Acidulant in food, (Jams, Preserved fruits, Fruit drinks) and pharmaceutical industries.

- It is mainly used in food and beverage industry (Jams, preserved fruits, fruit drinks)

- It is used is pharmaceuticals, and other industrial processes

- Citrate and citrate esters are used as plasticizers

- It is used as a chelating and sequestering agent (Tanning of animal skins)

Generally citric acid obtained from citrus fruits, pineapple etc., After the development of microbial fermentation, citric acid production becomes very cheap and easy cost effective.